Understanding Concrete Slurry Pumps: Essential Tools for Effective Material Handling

Release time:

May 04,2025

Concrete slurry pumps are specialized devices designed to transport slurry—a mixture of water and fine particles, often in the form of cement, sand, or other aggregates. These pumps play a critical role in construction and various industrial processes where material handling of viscous substances is required. Understanding the functionality, benefits, and operational principles of concrete slurry

Concrete slurry pumps are specialized devices designed to transport slurry—a mixture of water and fine particles, often in the form of cement, sand, or other aggregates. These pumps play a critical role in construction and various industrial processes where material handling of viscous substances is required. Understanding the functionality, benefits, and operational principles of concrete slurry pumps can help users make informed decisions regarding their applications.

One of the primary functions of a concrete slurry pump is to efficiently move slurry from one location to another. This is crucial in construction sites where concrete needs to be poured in specific areas, often at heights or distances that would be challenging to achieve using traditional methods. The pump's design allows it to handle thick and viscous materials without compromising performance.

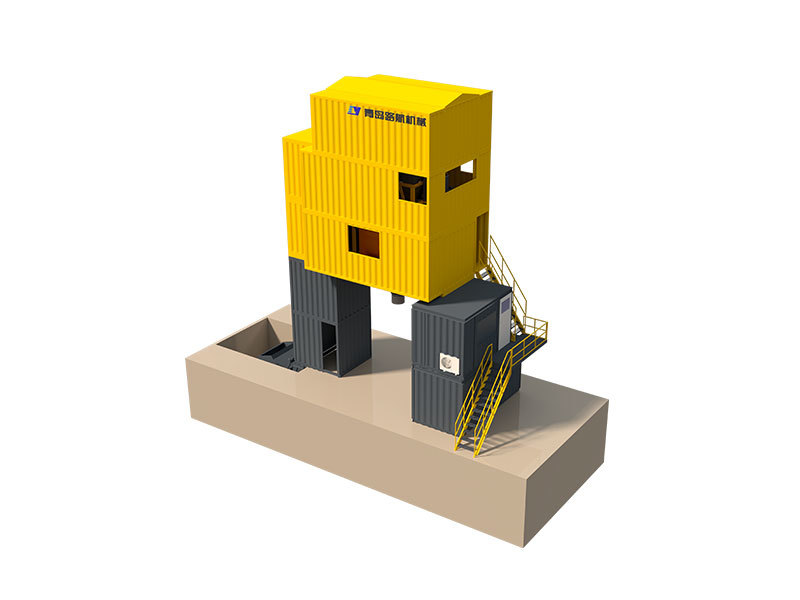

Concrete slurry pumps come in various configurations, including submersible and trailer-mounted options. Submersible pumps are often utilized in situations where the slurry needs to be pumped from below the surface, while trailer-mounted pumps offer mobility and can be easily transported to different job sites. The choice between these types largely depends on the specific requirements of the project.

Another significant advantage of using concrete slurry pumps is their capacity to maintain consistent flow rates. This reliability is vital in ensuring that construction schedules are met and that projects remain on track. Moreover, many concrete slurry pumps are designed with features that reduce wear and tear, thereby increasing their longevity and reducing maintenance costs. This makes them an economically viable option for contractors and construction firms.

The operational principles behind concrete slurry pumps involve various mechanisms, including centrifugal and positive displacement systems. Centrifugal pumps use rotational energy to move the slurry, while positive displacement pumps work by trapping a fixed amount of fluid and forcing it through the discharge pipe. Each type has its strengths, making it essential for users to choose the right pump based on the slurry’s characteristics and the specific job requirements.

In conclusion, concrete slurry pumps are essential tools in the industrial equipment landscape, particularly in construction. Their ability to transport viscous materials efficiently, combined with durable design and reliable performance, makes them indispensable for handling concrete and similar substances. Understanding the various types and operational principles can empower users to select the right pump for their needs, enhancing project efficiency and effectiveness. Whether you are involved in construction, mining, or any other industry requiring slurry management, knowing about concrete slurry pumps will undoubtedly benefit your operations.

Key words: