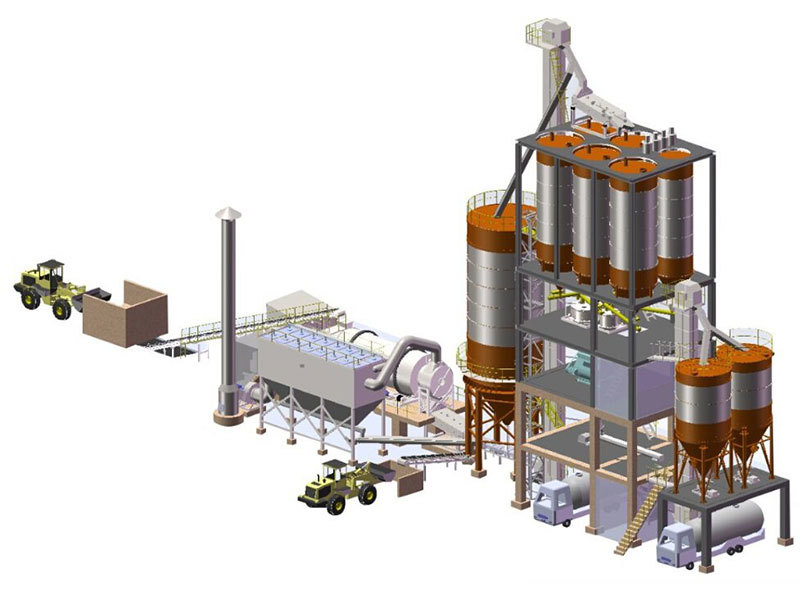

Structural composition of mobile mixing plant

Release time:

Oct 14,2024

Mainframe chassis: a cantilevered mixing mainframe chassis, which contains towing truck towing pins and parking legs

1. Mainframe chassis: a cantilevered mixing mainframe chassis, which contains towing truck towing pins and parking legs; on the chassis, the mixer, cement and water admixture weighing scale is placed; the periphery is equipped with inspection platforms and railings.

2. Control room: the control room is at the bottom of the chassis of the main machine, and the fully automatic control system of the mixing plant is installed inside; the control system is the same as that of the stationary mixing plant; the control room serves as the front support point of the whole plant in the working state, and the control room is put away and collected in the inner hollow of the bracket in the course of transferring and transporting; all the control lines do not need to be dismantled.

3. Aggregate batching and metering: this system is located at the back end of the whole plant, the upper part is aggregate (sand, stone) storage hopper, the storage hopper can be divided into 2 or 4 compartments, and set up heightening plate to increase the storage capacity, pneumatic operation in order to open the door, aggregate metering for a variety of materials cumulative metering method. The bottom is equipped with traveling rear axle and frame legs at work.

4. Belt conveyor frame: the frame is a truss structure connecting the chassis of the main machine and the batching frame of the aggregate, and the belt conveyor frame is installed inside; the main machine frame, the belt conveyor frame, and the batching frame are united to form the main structure of the whole mobile mixing plant.

5. Peripheral parts: cement silo and screw conveyor, the peripheral parts are integral parts no matter working or transportation, no need to disassemble, so they can be transported, disassembled and assembled as a whole.

6. Mixing machine: JS type forced mixer is generally adopted, which can quickly and evenly mix and complete the fluid and dry concrete.

Key words: