Maximizing Efficiency with Asphalt Drum Mixing Plants: A Comprehensive Guide

Release time:

Jul 07,2025

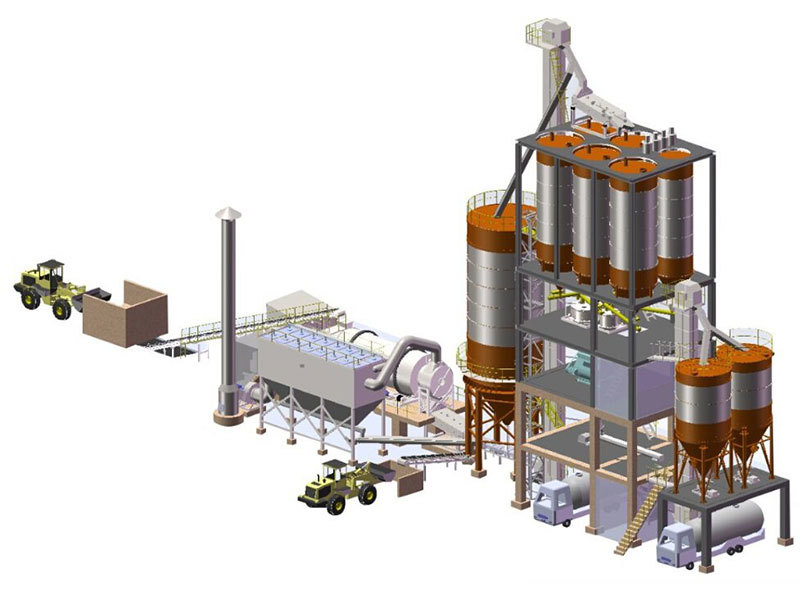

In the manufacturing of mixing machinery, particularly asphalt drum mixing plants, understanding their components and operational efficiency can significantly impact production outcomes. An asphalt drum mixing plant is a type of facility designed to produce asphalt for road construction projects through a continuous mixing process. This method allows for a more streamlined production line compared

In the manufacturing of mixing machinery, particularly asphalt drum mixing plants, understanding their components and operational efficiency can significantly impact production outcomes. An asphalt drum mixing plant is a type of facility designed to produce asphalt for road construction projects through a continuous mixing process. This method allows for a more streamlined production line compared to batch mixing plants, making it a popular choice in the industry.

One of the principal advantages of asphalt drum mixing plants is their ability to produce asphalt continuously. This capability is crucial for large-scale projects where time efficiency is vital. By integrating the drying and mixing processes into a single drum, the plant can reduce the overall production time, ensuring a steady supply of asphalt. This continuous flow also leads to more consistent quality in the final product, as the materials are uniformly mixed.

The technology behind asphalt drum mixing plants typically includes a fuel-efficient burner that heats the aggregate and dries it before mixing. This not only enhances the quality of the asphalt but also reduces energy consumption, contributing to a more sustainable production process. Professionals should pay attention to the type of fuel used, as this can impact both the operational costs and the environmental footprint of the plant.

Another important aspect to consider is the control system of the asphalt drum mixing plant. Modern plants are equipped with sophisticated control systems that allow for precise adjustments to the mixing process. This includes monitoring the temperature and flow rate of materials, which is essential for maintaining the desired asphalt mix specifications. By utilizing advanced technology, operators can ensure that the asphalt produced meets industry standards and client requirements.

In addition to operational efficiency, it is essential for professionals in the manufacturing sector to focus on maintenance practices for asphalt drum mixing plants. Regular maintenance ensures that the machinery operates smoothly and reduces the risk of unexpected downtime. Implementing a proactive maintenance schedule, which includes routine inspections and timely replacement of worn components, can significantly improve the lifespan and reliability of the plant.

Asphalt drum mixing plants also offer flexibility in terms of production capacity. Depending on the specific project requirements, these plants can be scaled to meet different output levels. This adaptability allows businesses to respond quickly to varying demands, making them an excellent choice for companies looking to expand their capabilities.

In conclusion, understanding the functionality and advantages of asphalt drum mixing plants is essential for professionals in the manufacturing and mixing machinery industry. By embracing innovative technology and implementing best practices, businesses can maximize efficiency and enhance the quality of their asphalt products.

One of the principal advantages of asphalt drum mixing plants is their ability to produce asphalt continuously. This capability is crucial for large-scale projects where time efficiency is vital. By integrating the drying and mixing processes into a single drum, the plant can reduce the overall production time, ensuring a steady supply of asphalt. This continuous flow also leads to more consistent quality in the final product, as the materials are uniformly mixed.

The technology behind asphalt drum mixing plants typically includes a fuel-efficient burner that heats the aggregate and dries it before mixing. This not only enhances the quality of the asphalt but also reduces energy consumption, contributing to a more sustainable production process. Professionals should pay attention to the type of fuel used, as this can impact both the operational costs and the environmental footprint of the plant.

Another important aspect to consider is the control system of the asphalt drum mixing plant. Modern plants are equipped with sophisticated control systems that allow for precise adjustments to the mixing process. This includes monitoring the temperature and flow rate of materials, which is essential for maintaining the desired asphalt mix specifications. By utilizing advanced technology, operators can ensure that the asphalt produced meets industry standards and client requirements.

In addition to operational efficiency, it is essential for professionals in the manufacturing sector to focus on maintenance practices for asphalt drum mixing plants. Regular maintenance ensures that the machinery operates smoothly and reduces the risk of unexpected downtime. Implementing a proactive maintenance schedule, which includes routine inspections and timely replacement of worn components, can significantly improve the lifespan and reliability of the plant.

Asphalt drum mixing plants also offer flexibility in terms of production capacity. Depending on the specific project requirements, these plants can be scaled to meet different output levels. This adaptability allows businesses to respond quickly to varying demands, making them an excellent choice for companies looking to expand their capabilities.

In conclusion, understanding the functionality and advantages of asphalt drum mixing plants is essential for professionals in the manufacturing and mixing machinery industry. By embracing innovative technology and implementing best practices, businesses can maximize efficiency and enhance the quality of their asphalt products.

Key words: