The Future of Construction: Integrating Cement Silos in Concrete Mixing Plants

Release time:

Aug 04,2025

The Future of Construction: Integrating Cement Silos in Concrete Mixing Plants Table of Contents 1. Introduction to Concrete Mixing Plants 2. The Role of Cement Silos in Modern Construction 3. Benefits of Integrating Cement Silos 3.1 Enhanced Efficiency and Productivity 3.2 Cost-Effectiveness and Waste Reduction 3.3 Improved Quality Control 4. Types of Cement Silos Used in the Industry 4.1 Bulk St

The Future of Construction: Integrating Cement Silos in Concrete Mixing Plants

Table of Contents

1. Introduction to Concrete Mixing Plants

2. The Role of Cement Silos in Modern Construction

3. Benefits of Integrating Cement Silos

3.1 Enhanced Efficiency and Productivity

3.2 Cost-Effectiveness and Waste Reduction

3.3 Improved Quality Control

4. Types of Cement Silos Used in the Industry

4.1 Bulk Storage Silos

4.2 Mobile Silos

4.3 Horizontal Silos

5. Technology Advancements in Cement Silos

5.1 Automation and IoT Integration

5.2 Smart Monitoring Systems

6. Future Trends in Cement Silo Technology

7. Case Studies: Successful Integration of Cement Silos

8. Frequently Asked Questions

9. Conclusion

1. Introduction to Concrete Mixing Plants

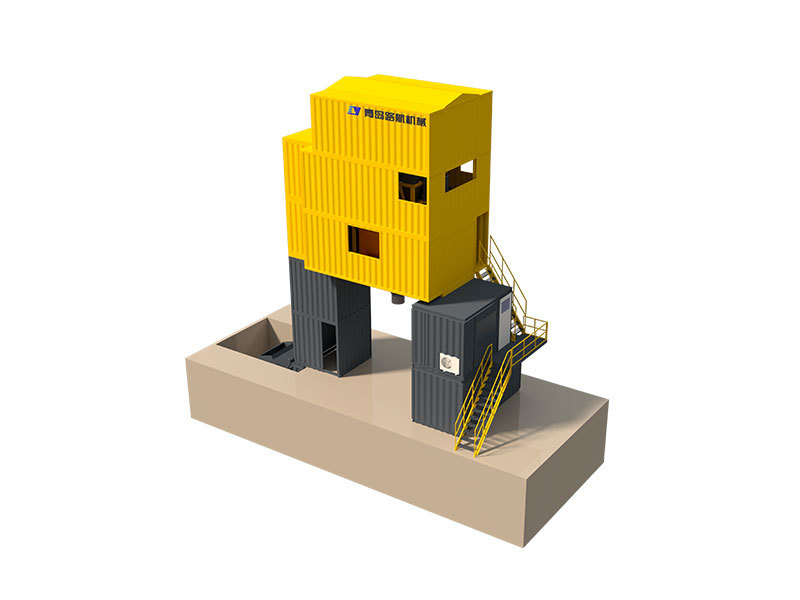

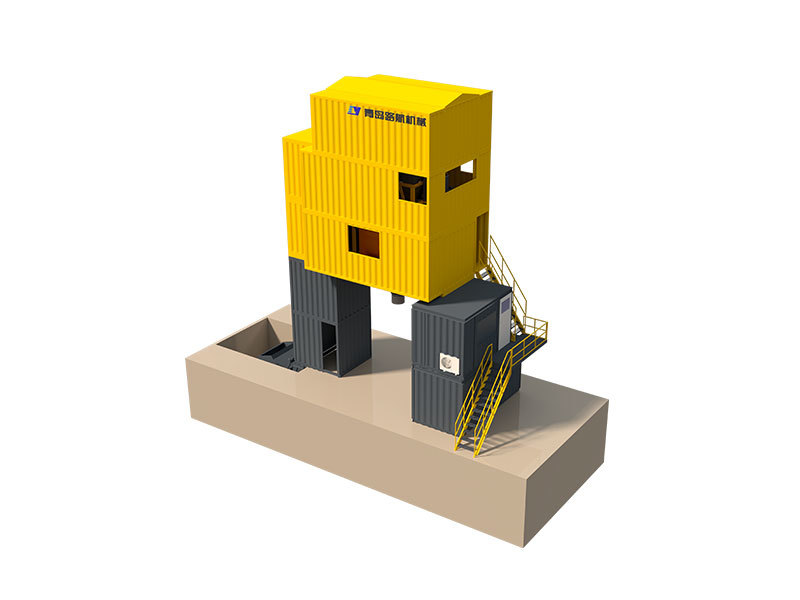

The construction industry is undergoing a **transformative shift**, particularly in the ways concrete is produced. Concrete mixing plants serve as the heart of this process, integrating various materials to create high-quality concrete efficiently. As construction demands continue to rise, the need for innovative solutions becomes increasingly essential. One such solution is the **integration of cement silos**, which are pivotal to enhancing the performance of concrete mixing plants.

2. The Role of Cement Silos in Modern Construction

Cement silos are essential storage units that hold bulk cement, a primary ingredient in concrete production. Their role in **modern construction** cannot be overstated. By providing a stable supply of cement, silos facilitate continuous production cycles, reduce downtime, and enhance operational efficiency. Moreover, the strategic placement of these silos within concrete mixing plants ensures that materials are readily available, streamlining the mixing process.

3. Benefits of Integrating Cement Silos

Integrating cement silos into concrete mixing plants offers a multitude of advantages that contribute to the overall improvement of construction operations.

3.1 Enhanced Efficiency and Productivity

One of the most significant benefits of integrating cement silos is the enhancement of **efficiency and productivity**. With a constant supply of cement, concrete mixing plants can operate without interruptions. This leads to faster mixing cycles and, ultimately, quicker project completion times. The automation of filling and discharging processes also minimizes labor-intensive tasks, promoting a more efficient workflow.

3.2 Cost-Effectiveness and Waste Reduction

Cost management is a critical aspect of construction projects. By utilizing cement silos, companies can significantly reduce **material waste**. Silos protect cement from environmental factors that may lead to spoilage or contamination, ensuring that the material remains in optimal condition. Additionally, bulk purchasing of cement can lead to substantial cost savings, making integration a financially sound decision.

3.3 Improved Quality Control

Concrete quality is paramount in construction, and cement silos contribute to this aspect significantly. By storing cement in controlled environments, silos help maintain consistency in material properties. This leads to higher quality concrete, which is crucial for meeting industry standards and regulatory requirements.

4. Types of Cement Silos Used in the Industry

The construction industry employs various types of cement silos, each designed to meet specific needs and operational requirements.

4.1 Bulk Storage Silos

Bulk storage silos are the most commonly used type in large-scale operations. These silos can hold significant quantities of cement, making them ideal for extensive concrete production. Constructed from durable materials, bulk silos can withstand harsh environmental conditions, ensuring long-term reliability.

4.2 Mobile Silos

Mobile silos offer flexibility, allowing for easy relocation based on project needs. These silos are particularly useful for smaller projects or sites with space constraints. Their design facilitates quick setup and breakdown, making them an attractive option for contractors who require adaptability.

4.3 Horizontal Silos

Horizontal silos are gaining popularity for their space-saving design. These silos are ideal for sites with limited vertical space and can be integrated seamlessly into existing concrete mixing plants. Their low profile makes them easier to transport and set up, providing another layer of convenience for construction projects.

5. Technology Advancements in Cement Silos

As the construction industry embraces **technological advancements**, cement silos are not left behind. Innovations are making these storage units smarter and more efficient.

5.1 Automation and IoT Integration

The integration of **Internet of Things (IoT)** technology in cement silos allows for real-time monitoring and automation of operations. Sensors can track the level of cement in the silo, providing alerts when supplies are low. This automation reduces the risk of running out of materials and optimizes inventory management.

5.2 Smart Monitoring Systems

Smart monitoring systems enhance the functionality of cement silos by providing data analytics on usage patterns and performance. These insights can help operators make informed decisions regarding maintenance, production schedules, and inventory management, ultimately improving overall plant efficiency.

6. Future Trends in Cement Silo Technology

The future of cement silos looks promising, with several trends emerging that will shape their development:

1. **Sustainability Initiatives**: As the construction industry strives for sustainability, cement silos will evolve to incorporate eco-friendly materials and energy-efficient designs.

2. **Advanced Materials**: Innovations in materials science may lead to the development of lighter, stronger silos that can hold larger quantities without compromising safety.

3. **Integration with Renewable Energy**: Future silos may incorporate renewable energy solutions, such as solar panels, to reduce operational costs and environmental impact.

7. Case Studies: Successful Integration of Cement Silos

Looking at real-world examples can provide valuable insights into the successful integration of cement silos within concrete mixing plants:

- **Case Study 1: Large-Scale Construction Project**: A major infrastructure project implemented bulk cement silos, leading to a 30% reduction in material costs and a 25% faster project completion rate.

- **Case Study 2: Urban Development**: An urban developer utilized mobile silos to adapt to changing site conditions, resulting in improved workflow and minimized downtime.

These case studies exemplify how integrating cement silos can lead to tangible benefits in efficiency, cost savings, and project success.

8. Frequently Asked Questions

FAQ 1: What are the main types of cement silos?

The main types of cement silos are bulk storage silos, mobile silos, and horizontal silos. Each type serves different operational needs.

FAQ 2: How do cement silos improve concrete quality?

Cement silos maintain controlled environments, protecting cement from contamination and ensuring consistent material properties for better concrete quality.

FAQ 3: What are the benefits of automated cement silos?

Automated cement silos offer improved efficiency, real-time monitoring, and reduced labor costs by streamlining filling and discharging processes.

FAQ 4: Can cement silos be relocated easily?

Mobile silos are designed for easy relocation, making them ideal for projects that require flexibility in site management.

FAQ 5: How can technology enhance cement silo operations?

Technologies like IoT and smart monitoring systems optimize inventory management, improve maintenance schedules, and enhance overall efficiency in cement silo operations.

9. Conclusion

The integration of cement silos in concrete mixing plants represents a **significant advancement** in the construction industry. As we continue to embrace technology and innovation, cement silos will play a crucial role in enhancing efficiency, reducing costs, and improving sustainability. The future of construction is bright, and those who invest in these advancements will undoubtedly gain a competitive edge in a rapidly evolving market. By understanding and adapting to these changes, we can pave the way for a more efficient and sustainable construction industry.

Key words: