Top Features to Look for in an Automatic Ready-Mix Stationary Concrete Batch Plant

Release time:

May 13,2025

Top Features to Look for in an Automatic Ready-Mix Stationary Concrete Batch Plant Introduction to Automatic Ready-Mix Stationary Concrete Batch Plants In the construction industry, the efficiency and quality of concrete production are paramount. An **automatic ready-mix stationary concrete batch plant** is a crucial investment for companies focused on delivering consistent, high-quality concrete.

Top Features to Look for in an Automatic Ready-Mix Stationary Concrete Batch Plant

Introduction to Automatic Ready-Mix Stationary Concrete Batch Plants

In the construction industry, the efficiency and quality of concrete production are paramount. An **automatic ready-mix stationary concrete batch plant** is a crucial investment for companies focused on delivering consistent, high-quality concrete. Selecting the right batch plant involves understanding the key features that can enhance productivity, reduce costs, and ensure compliance with industry standards.

This article explores the **top features** you should consider when choosing an automatic ready-mix stationary concrete batch plant. From automation capabilities to environmental considerations, we provide a detailed overview to help you make an informed decision.

Table of Contents

1. Understanding Concrete Batch Plants

2. Importance of Automation in Batch Plants

3. Key Features of Automatic Ready-Mix Stationary Concrete Batch Plants

3.1 Advanced Control Systems

3.2 High-Quality Mixing Technology

3.3 Energy Efficiency and Sustainability

3.4 Modular Design and Customization

3.5 Maintenance and Support Services

4. How to Choose the Right Batch Plant for Your Needs

5. Frequently Asked Questions (FAQs)

6. Conclusion

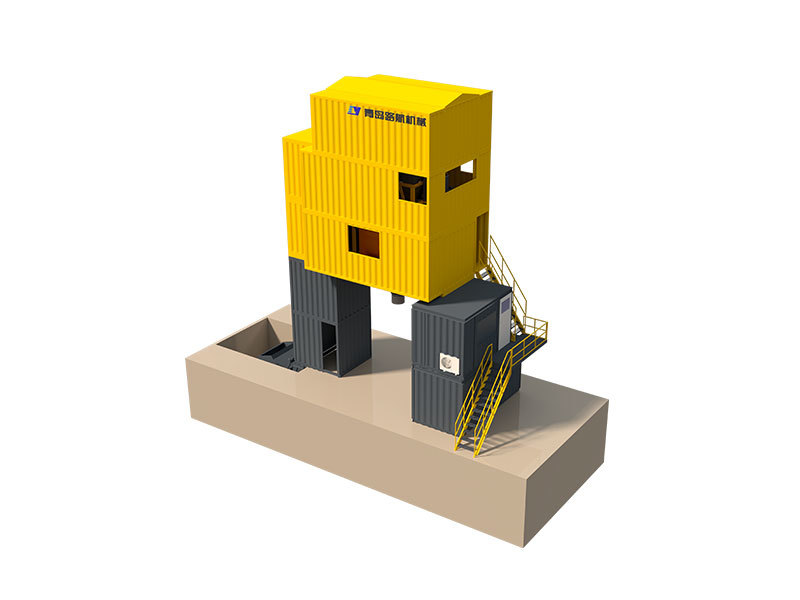

Understanding Concrete Batch Plants

Concrete batch plants are facilities where raw materials are combined to produce concrete. These plants come in various configurations, including stationary and mobile types. An **automatic ready-mix stationary concrete batch plant** is specifically designed for large-scale production, often found in commercial construction projects.

The primary components of a batch plant include aggregate bins, a mixer, a control system, and a concrete delivery system. Each component plays a vital role in ensuring that the concrete produced meets the required specifications regarding strength, durability, and consistency.

Importance of Automation in Batch Plants

Automation in concrete production significantly enhances efficiency, accuracy, and safety. An automated system minimizes human error by controlling the mixing ratios, timing, and delivery processes. This ensures that the produced concrete meets precise specifications every time, which is critical for large-scale projects where quality assurance is non-negotiable.

Moreover, automation reduces labor costs and increases the overall productivity of the plant, allowing for quicker turnaround times and improved output.

Key Features of Automatic Ready-Mix Stationary Concrete Batch Plants

Advanced Control Systems

A state-of-the-art control system is fundamental to any automatic ready-mix stationary concrete batch plant. Look for features such as:

- **User-Friendly Interface**: An intuitive interface allows for quick adjustments and monitoring.

- **Remote Monitoring and Control**: This feature enables operators to manage operations from a distance, enhancing flexibility.

- **Data Logging and Reporting Capabilities**: Tracks production metrics, ensuring compliance with quality standards and assisting in troubleshooting.

High-Quality Mixing Technology

The quality of the concrete produced heavily depends on the mixing technology employed. Features to consider include:

- **Twin-Shaft Mixers**: These mixers offer superior homogeneity and are ideal for producing high-strength concrete.

- **Planetary Mixers**: Known for their efficiency in producing small batches and specialty mixes.

- **Continuous Mixing Systems**: For projects requiring a constant supply of concrete, continuous mixers provide an uninterrupted flow.

Energy Efficiency and Sustainability

In today’s construction landscape, sustainability is a priority. An energy-efficient plant not only reduces operational costs but also minimizes environmental impact. Look for:

- **Variable Frequency Drives (VFDs)**: These help control the energy consumption of motors.

- **Recycling Systems**: Some batch plants incorporate systems that recycle water and aggregates, reducing waste.

- **Sustainable Materials Use**: Features that allow the use of alternative materials should also be on your checklist.

Modular Design and Customization

A modular design allows for flexibility in the layout and expansion of the plant. This is particularly beneficial for companies that anticipate changes in production capacity or project requirements. Customization options can include:

- **Additional Aggregate Bins**: For storing different materials.

- **Customized Mixing Solutions**: Tailor the mixers to meet specific project needs.

- **Scalable Production Capacity**: Easily modify the plant to increase or decrease output.

Maintenance and Support Services

Regular maintenance is crucial for the longevity and efficiency of a concrete batch plant. When evaluating options, consider:

- **Warranty and Service Packages**: Comprehensive support packages can save costs in the long run.

- **Availability of Spare Parts**: Ensure that parts are readily available to minimize downtime.

- **Training Programs**: Quality training for operators ensures optimal usage and maintenance of the plant.

How to Choose the Right Batch Plant for Your Needs

When selecting an automatic ready-mix stationary concrete batch plant, consider the following factors:

- **Project Size and Scope**: Analyze your project's requirements to determine the necessary capacity and features.

- **Location and Accessibility**: Assess the site where the plant will be installed and its accessibility for delivery and maintenance.

- **Budget Constraints**: Evaluate your financial resources and consider the long-term return on investment of higher-quality options.

Conducting a thorough market comparison and seeking expert opinions can also guide your decision-making process.

Frequently Asked Questions (FAQs)

1. What is an automatic ready-mix stationary concrete batch plant?

An automatic ready-mix stationary concrete batch plant is a facility designed to produce concrete through an automated process, ensuring consistent quality and efficiency in large-scale production.

2. How does automation improve concrete production?

Automation enhances concrete production by minimizing human error, increasing efficiency, reducing labor costs, and ensuring precise mixing ratios.

3. What are the benefits of using high-quality mixing technology?

High-quality mixing technology ensures superior homogeneity and strength in concrete, which is vital for meeting project specifications and regulatory standards.

4. Why is energy efficiency important in a concrete batch plant?

Energy efficiency reduces operational costs, minimizes environmental impact, and contributes to sustainable construction practices.

5. How can I maintain my concrete batch plant effectively?

Regular maintenance, which includes inspections, timely repairs, and operator training, is essential for the optimal performance and longevity of a concrete batch plant.

Conclusion

Choosing the right **automatic ready-mix stationary concrete batch plant** is a crucial decision that can significantly impact your construction operations. By focusing on features such as advanced control systems, high-quality mixing technology, energy efficiency, modular design, and maintenance support, you can ensure that your investment meets your operational needs while delivering consistent, high-quality concrete.

As the construction industry continues to evolve, embracing modern solutions such as automated batch plants will not only enhance productivity but also contribute to a more sustainable future. By considering the insights shared in this article, you are better equipped to make an informed decision that aligns with your business goals.

Key words: