Asphalt mixing plant

- Commodity name: Asphalt mixing plant

KEYWORDS:

Luhang Machinery Equipment

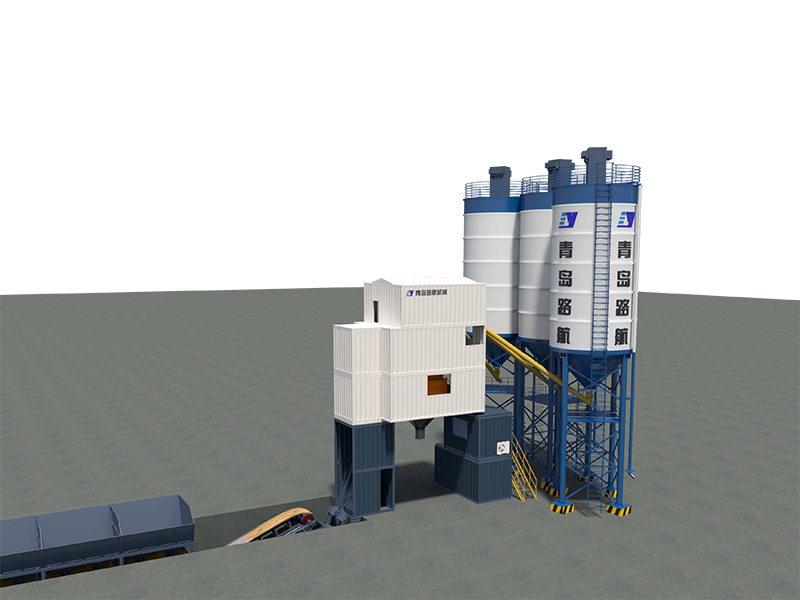

customized Concrete mixing plant containing cement silo

newest Box Mixing Plant

quality Environment-friendly mixing plant

china Vehicle mobile mixing plant

china Vehicle-Mounted Mobile Mixing Plant

- Product Description

-

1. The asphalt mixing equipment adopts modular design and compact structure.

2. The mixing tank has a large capacity of mixing space, the blade and liner are made of nickel hard alloy, and the service life is more than 100,000 mixing batches.

3. The unique drop correction function and asphalt secondary weighing function ensure the accuracy of measurement and the accuracy of oil stone ratio. Batching system

4. Each silo adopts variable frequency speed regulating motor to control the belt feeder, and uses a set of hard gear reducer with compact structure. The special anti-clamping and anti-wear design is equipped with a wear-resistant fender belt. The operation is safe, reliable and has a long life. Dust control system

5. The dust removal system uses the German technology to integrate the first inertial dust collector and the second cloth bag dust collector into one, fully saving the floor area, the use of high temperature resistant, flame retardant, non-toxic, high strength aramide fiber fabric, the dust concentration is less than 50mg/Nm3, the system has an overtemperature protection system.

Technical Parameters

Models LBG1500 LBG2000 LBG3000 LBG4000 LBG5000 Cold storage: number x capacity 4×10m³ 5×15m³ 5×20m³ 6×20m³ 6×20m³ Roller size: diameter x length 1.8m×7.5m 2.25m×9m 2.5m×10m 2.8m×1lm 2.9m×12.5m Maximum drying capacity (moisture content 5%) 120t/h 160t/h 240t/h 320t/h 400t/h Fuels Light oil/heavy oil/natural gas (optional) Dust removal method Primary gravity dust removal + secondary bag dust removal Mixing machine capacity 1.5t 2t 3t 4t 5t Mixing method Horizontal Twin-shaft Forced Mixing Finished product silo volume 15m³+15m³ 15m³+15m³ 22m³+22m³ 28m³+28m³ 30m³+30m³ Control system Cloud interconnection, dual-machine dual-control system Standard footprint 35m×35m 40m×40m 40m×45m 43m×47m 50m×50m Rated Capacity 120t/h 160t/h 240t/h 320t/h 400t/h Product Photograph

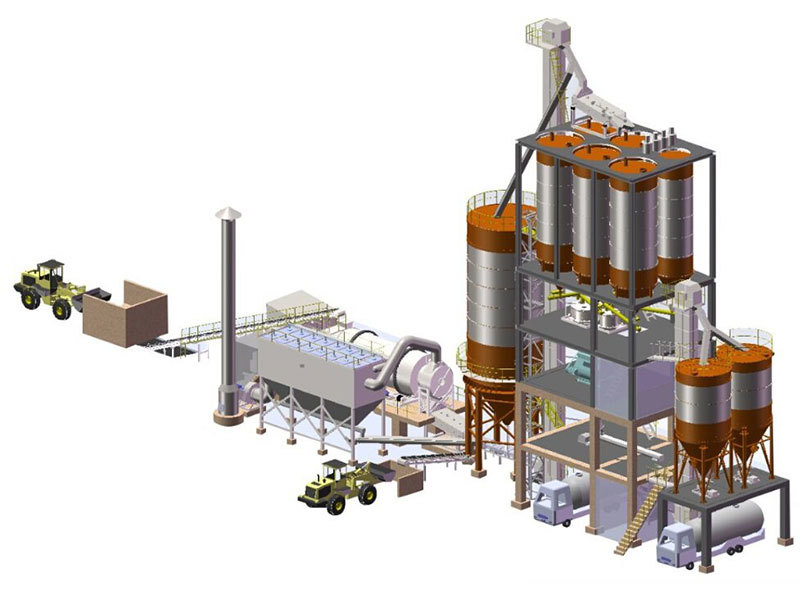

An Asphalt Mixing Plant is a vital facility in road construction and related infrastructure projects.

At the core of the plant is the mixing unit. It is designed to blend aggregates such as gravel and sand, with asphalt binder in accurate proportions. This precise mixing is crucial for achieving the desired quality and performance of the asphalt mixture.

The plant also features storage areas for aggregates. These storage bins are carefully constructed to ensure proper segregation and easy access for the supply of materials to the mixing unit. There are also tanks or containers for storing the liquid asphalt.

A well - equipped Asphalt Mixing Plant has a conveyor system. This system transports the aggregates from the storage areas to the mixing unit efficiently, ensuring a continuous supply of materials for uninterrupted production.

In addition, modern asphalt mixing plants often incorporate advanced control systems. These systems can monitor and adjust the mixing process parameters, such as temperature and mixing time, in real - time. Temperature control is especially important as it affects the workability and final quality of the asphalt.

Quality control measures are also an integral part of an asphalt mixing plant. Samples are regularly taken and tested to ensure that the produced asphalt meets the required specifications for strength, durability, and other performance - related criteria. Overall, an asphalt mixing plant is essential for producing high - quality asphalt mixtures that are used to build durable roads, parking lots, and other paved surfaces.

Case Studies

Standard Mixing Plant

Standard Mixing Plant

Standard Mixing Plant

Product Details Photos

Shipping Photos

Shipping Photos

Shipping Photos

Factory Show

The company's mainbusiness includes concrete mixing, equipment.concrete recycling environmental protectionequipment, dust removal equipment, andsales services

FAQ

What certifications do your products have?

Do you provide samples Is it free or extra?

Once the products received by customer were found not comply with the products or contract demands, what will you do?

WHY CHOOSE US

Qingdao Luhang Machinery Equipment Co., Ltd.

Qingdao Luhang Machinery Equipment Co., Ltd.is a company dedicated to theresearch and development, manufacturing,sales, and after-sales service of concretemixing plant equipment. The company's mainbusiness includes concrete mixing, equipment.concrete recycling environmental protectionequipment, dust removal equipment, andsales services, We are dedicated to serving youin our three major production bases located inJinan, Shandong, Qingdao, Shandong, andChangsha, Hunan.

Product inquiry

Note: Please leave your mobile phone and email address, our professionals will contact you as soon as possible!